GP Rotary disc vacuum filter

The GP disc filter is a device that operates using filter cloth as the filtration medium. Particles are trapped on the surface of the medium, forming a filter cake, while the liquid flows through the filtration medium, achieving the purpose of solid-liquid separation.

Keyword:

Classification:

Product Display

Brief Introduction of Equipment

GP Rotary disc vacuum filter is a kind of work based on the principle of capillary micropores, the use of microporous ceramic as a filter medium, particles are trapped in the medium surface to form a filter cake, while the liquid through the filter medium outflow, to achieve the purpose of solid-liquid separation.

Rotary disc vacuum filter have been widely used in iron concentrate, zinc concentrate, It can be used for filtration and dewatering of mineral concentrates such as sulfur concentrate, copper concentrate, nickel concentrate, molybdenum concentrate, lead concentrate, tungsten concentrate, manganese concentrate, vanadium ore, aluminum concentrate, gold concentrate, non-metallic concentrate and solid-liquid separation of coal, fine chemical industry, paper making, pharmaceutical, chemical fiber, food, environmental protection and other industries.

Four major product lines:

Technical Specifications of the φ2100 Series Disc Filter Machine

Filter disc diameter (mm) | Middle 2100 | |||||||||||

Filtration area (m²) | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 | |

Number of filter discs | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 | |

Spindle motor power (kW) | 2.2 | 3 | 4 | 5.5 | ||||||||

Stirring motor power (kW) | 3 | 4 | 5.5 | 7.5 | ||||||||

Discharge method | Back-blowing | |||||||||||

Outside Type Inch Inch | Length (mm) | 2145 | 2535 | 2925 | 3315 | 3705 | 4095 | 4485 | 4875 | 5265 | 5655 | 6435 |

Width (mm) | 2480 | |||||||||||

Height (mm) | 2690 | |||||||||||

Processing capacity | 0.85–1.2 t/h · m² (processing 0.85–1.2 tons of iron concentrate per square meter per hour) 0.2–1.2 t/h·m² (Processing capacity varies depending on the material, ranging from 0.2 to 1.2 tons per square meter per hour) | |||||||||||

![]() Technical Specifications of the Φ2600 Series Disc Filter Machine

Technical Specifications of the Φ2600 Series Disc Filter Machine

Filter disc diameter (mm) | φ2600 | ||||||||

Filtration area (m²) | 40 | 48 | 56 | 64 | 72 | 80 | 88 | 96 | |

Number of filter discs | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

Spindle motor power (kW) | 5.5 | 7.5 | 11 | ||||||

Stirring motor power (kW) | 7.5 | 11 | 15 | ||||||

Discharge method | Back-blowing | ||||||||

Outside Type Inch Inch | Length (mm) | 4435 | 4885 | 5335 | 5785 | 6235 | 6685 | 7135 | 7585 |

Width (mm) | 3300 | ||||||||

Height (mm) | 3200 | ||||||||

Processing capacity (t/h · m²) | 0.85–1.2 t/h · m² (processing 0.85–1.2 tons of iron concentrate per square meter per hour) 0.2–1.2 t/h·m² (Processing capacity varies depending on the material, ranging from 0.2 to 1.2 tons per square meter per hour) | ||||||||

Technical Specifications of the φ3100 Series Disc Filter Machine

Filter disc diameter mm ) | Middle 3100 | |||||||

Filtration area (m²) | 48 | 60 | 72 | 84 | 96 | 108 | 120 | |

Number of filter discs | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

Spindle motor power kw ) | 5.5 | 7.5 | 11 | |||||

Stirring motor power kw ) | 7.5 | 11 | 15 | |||||

Discharge method | Back-blowing | |||||||

Outside Type Inch Inch | Long mm ) | 4235 | 4735 | 5235 | 5735 | 6235 | 6735 | 7235 |

Wide mm ) | 4280 | |||||||

Tall mm ) | 3740 | |||||||

Processing capacity (t/h ·m²) | 0.85-1.2t/h ·m² (0.85 tons of iron concentrate processed per square meter per hour) Tons - 1.2 tons) 0.2–1.2 t/h ·m² (material handling capacity per square meter per hour for different materials) Different) | |||||||

Technical Specifications of the φ4100 Series Disc Filter Machine

Filter disc diameter (mm) | Middle 4100 | ||||||||

Filtration area (m²) | 120 | 140 | 160 | 180 | 200 | 220 | 240 | 260 | |

Number of filter discs | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | |

Spindle motor power (kW) | 11 | 15 | 18.5 | ||||||

Stirring motor power (kW) | 15 | 18.5 | 22 | ||||||

Discharge method | Back-blowing | ||||||||

Outside Type Inch Inch | Long (mm) | 5565 | 6115 | 6665 | 7215 | 7765 | 8315 | 8865 | 9415 |

Wide (mm) | 5080 | ||||||||

Tall (mm) | 4640 | ||||||||

Processing capacity (t/h · m²) | 0.85–1.2 t/h · m² (processing 0.85–1.2 tons of iron concentrate per square meter per hour) 0.2–1.2 t/h·m² (Processing capacity varies depending on the material, ranging from 0.2 to 1.2 tons per square meter per hour) | ||||||||

Equipment Features

1. Filter fan:

Addressing the existing shortcomings of commonly used filter fans, our company has redesigned a specialized, new-type filter fan tailored specifically to the unique requirements of the mineral processing industry.

(1) The surface is smooth, with evenly distributed dewatering holes of an optimal porosity. Additionally, the edges of both the filter fan and reinforcing ribs are rounded, which not only enhances the dewatering efficiency but also extends the service life of the filter cloth.

(2) The filter fan head features a chamfered edge for enhanced strength, and the bottom of the filter fan is equipped with reinforcing ribs, making it resistant to damage or breakage during assembly and disassembly.

(3) The rib orientation forms a more optimal angle with the central line of the filter fan, resulting in lower fluid resistance. Additionally, the large effective area of the filter fan enhances the filtration machine's processing capacity.

(4) The wall thickness of the filter fan has been increased by 1/3 compared to standard models, and its weight has also risen by 1/3 accordingly. This makes it one of the most structurally sound and robust filter fans currently available on the domestic market, with an average lifespan extended by 1.5 to 2 times.

2. Spindle and Filter Tube:

(1) The filter tubes (including the shaft ends) are made from high-strength, wear-resistant ceramic-composite steel pipes with thick walls, making them highly resistant to abrasion and extending their lifespan by more than two to three times.

(2) The flange connection at the interface between the filter tube and the filter fan has been eliminated, replaced instead by direct welding with mold positioning. This eliminates the risk of aging in the original flange-mounted leak-proof rubber gasket, thereby eliminating potential air leakage points.

(3) Each filter fan features a single pressure plate, with both ends secured tightly using stainless steel bolts and nuts—resistant to rust and easy to replace, significantly reducing labor intensity while simplifying the maintenance of the filter cloth.

3. Mixing:

Addressing the unique properties of iron ore powder and the current market challenges—such as frequent leaks in filtration machines and the lack of durability in existing mixing systems—our company has implemented the following advanced mixing equipment, achieving outstanding results and earning widespread praise from our customers.

(1) Add a permanent magnet—preventing mineral powder from entering the mixing sleeve;

(2) Use water sealing;

The groove beneath the stirring shaft is coated with a corundum-based polymer wear-resistant layer to prevent abrasion of the槽体 steel plates.

(4) Sealed with an axial skeleton-type sealing ring;

(5) The shaft surface is chrome-plated for enhanced rust resistance;

4. Trough Body

The groove beneath the stirring shaft is coated with a corundum-based polymer wear-resistant layer to prevent abrasion of the槽体 steel plates.

5. Control disc, friction pads:

Made from specially formulated wear-resistant boron-phosphorus cast iron, it combines strength with flexibility, ensuring excellent sealing performance and extending service life by 2 to 3 times.

6. Lubrication and Cleaning:

Centralized multi-point automatic lubrication using a dry oil pump ensures smooth equipment operation. The filter cloth is cleaned automatically with a dedicated cleaning device, maintaining excellent dewatering performance.

7. Electronic Control:

Variable-frequency speed control is used, adjusting based on the material's concentration and flow rate to achieve optimal performance.

Running Video

Contact Us

Contact E-mail

Contact Address

33 Wenzhou Street, Haiyang Economic Development Zone, Yantai, Shandong

Provide you with complete solid-liquid separation products and industry solutions

Committed to building strategic partnerships with users, user needs-oriented, in-depth study of industry characteristics, targeted optimization of product structure, focusing on user experience

Company establishment time

Technical center has more than 20 staff

Rich experience in filter design

Partners

How are we different from other suppliers?

At any time, we can provide customers with filter design solutions that meet the on-site process.

Rich industry experience

We are committed to providing a full range of solid-liquid separation products and solutions. With years of industry accumulation and experience, we have deep professional knowledge and technical strength. We are convinced that through our professional services and continuous innovation, we can help customers achieve greater success in the field of solid-liquid separation.

Wide range of product applications

Today, when environmental protection has increasingly become the focus of development, Yantai Nuclear One has always followed the pace of the industry, paid close attention to the latest developments in the filtration industry, and has deep involvement in many fields such as environmental protection, medicine, food, chemical industry, and mining.

Product customization

We always pay attention to customer needs, and can customize efficient filter design for customers at any time according to on-site process requirements. Our team pays attention to detail and strives for perfection to ensure that each filter can meet the unique needs of customers. At the same time, we provide end-to-end service support, from design, production to installation and commissioning, to protect the interests of customers in an all-round way.

Superior price-performance ratio

This source manufacturer has extraordinary strength, integrating R & D, manufacturing and sales, and has the ability to control the whole chain from the source to the terminal. In terms of cost performance, the manufacturer has made great efforts to provide high quality products at reasonable prices, and has won the trust and praise of customers.

Perfect service

We are committed to providing customers with a satisfactory service experience. No matter what problems you encounter, we will actively respond and solve them quickly. Our service team is professional and efficient, always paying attention to customer needs, ensuring that you are carefree in the process of using our products

Plant Equipment

According to the development of the filtration industry, we closely follow the new technologies and processes in the industry to ensure the high quality and high reliability of the products.

We are interested in our products.

Enter your contact information and we will contact you as soon as possible.

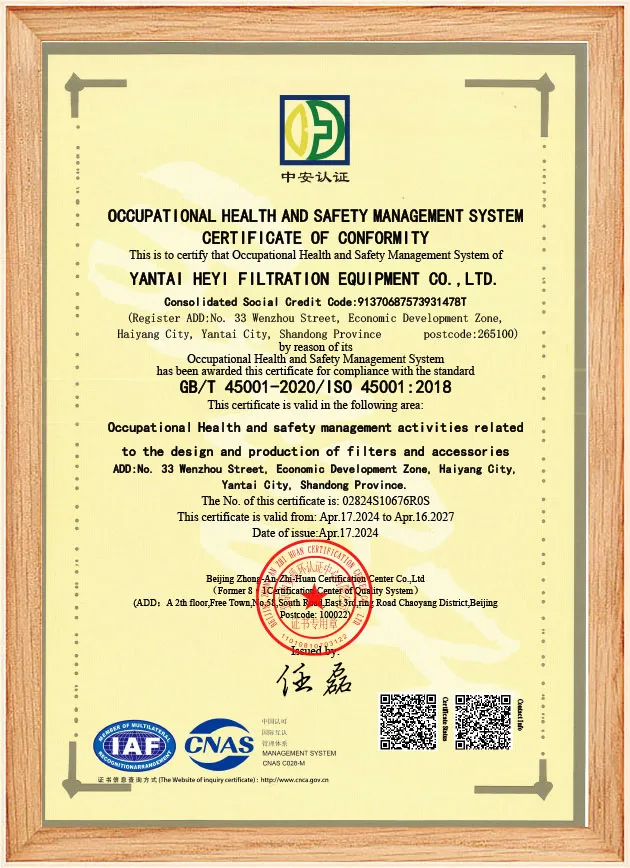

Quality Inspection

Rich experience in filter design, access to dozens of filter-related technology patents, ready to provide customers with on-site process to meet the filter design

Customer Visits

Provide you with complete solid-liquid separation products and industry solutions

Packaging Delivery

Committed to building strategic partnerships with users, user needs-oriented, in-depth study of industry characteristics, targeted optimization of product structure, focusing on user experience

Industry Solutions

Focus on environmental protection, medicine, food, chemical, mining and other enterprises, to provide perfect solid-liquid separation products and solutions

Hot Products

Expand the field and develop steadily. The company has gradually become a professional filter manufacturer integrating "Nuclear One" brand DU rubber belt vacuum filter, PBF mobile disc vacuum filter, TC ceramic filter, GP fixed disc filter, LX full-automatic centrifuge, HVPF full-automatic vertical filter press, DY belt press dewatering machine and its control system design and system debugging services.