Ceramic filter press

Under the action of pressure difference, the liquid (or gas) in the suspension passes through a permeable medium (filter medium), while solid particles are retained by the medium, thus achieving the separation of liquid and solid.

Keyword:

Classification:

Product Display

Product Introduction

The ceramic filter press is a dewatering device, mainly composed of ceramic filter plates, roller systems, stirring systems, feeding and discharging systems, vacuum systems, filtrate discharge systems, scraping systems, backwashing systems, combined cleaning (ultrasonic cleaning, automatic acid cleaning) systems, fully automatic control systems, tank bodies, and frames.

Its basic principle: Under the action of pressure difference, the liquid (or gas) in the suspension passes through a permeable medium (filter medium), and solid particles are retained by the medium, thus achieving the separation of liquid and solid.

The production process runs fully automatically and can freely adjust the operating speed, feed amount, and washing water amount according to production needs. The TC vacuum filter press has reached an internationally advanced level after years of development and is widely used in industries such as power environmental protection, mining, chemical, metallurgy, papermaking, food, pharmaceuticals, and coal.

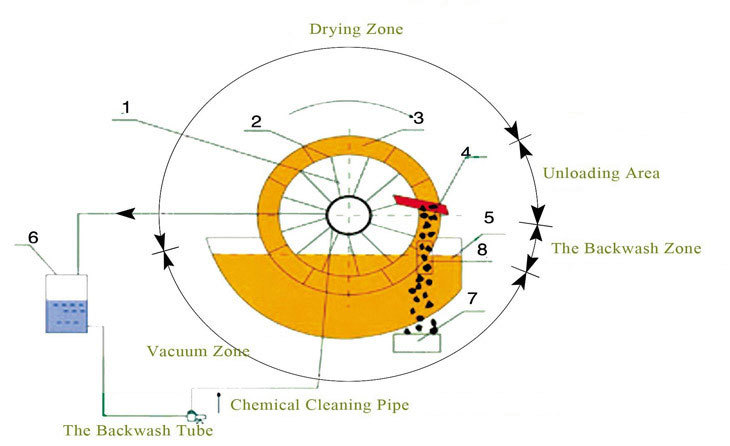

Working Principle of Ceramic Vacuum Filter Press

The ceramic filter press system adopts PLC full automatic control and is equipped with devices such as frequency converters, liquid level gauges, and metering pumps. When starting, the slurry valve is monitored by the level gauge to control the slurry liquid level. The filtrate in the vacuum tank is detected by the level gauge, and when it reaches the high level, the PLC control system quickly opens the filtrate pump outlet valve for rapid drainage. It can also adopt remote control or centralized control according to different user requirements.

Our company's filter press tank body is made of corrosion-resistant stainless steel or surface-lined with polytetrafluoroethylene, serving the purpose of loading slurry. The stirring system stirs the mixed materials in the tank body to avoid rapid sedimentation of materials; the ceramic filter plates are installed on the roller, which rotates under the drive of a continuously variable speed reducer. The filter medium used in the ceramic filter press is ceramic filter plates, eliminating the need for filter cloth, reducing production costs. During discharging, there is a gap of about 1mm between the scraper and the filter plate to prevent mechanical wear and extend the service life.

The specific production process is as follows:

Slurry Absorption Process: Driven by the driving device, the roller rotates with the filter plate around the main shaft towards the scraper direction. Under the negative pressure of the vacuum pump, the ceramic filter plate submerged in the slurry absorbs the slurry, and solid materials are adsorbed on the surface of the filter plate, while the filtrate is drawn into the filtrate tank and discharged by the filtrate pump.

Drying Process: The filter plate rotates out of the liquid surface, and under the negative pressure generated by the vacuum pump, the filter cake adsorbed on the surface of the filter plate is dried, and the filtrate is drawn into the filtrate tank and discharged by the filtrate pump.

Scraping: When the filter plate with the dried filter cake turns past the scraper, the scraper scrapes off the filter cake, which is then transported to the destination by conveying equipment.

Backwashing Process: After scraping off the filter cake, the filtrate pump sends a portion of the filtrate through the cleaning pipeline and distribution head into the filter plate, washing away the residual materials on its surface from the inside out, maintaining the filtration efficiency of the filter plate.

Combined Cleaning Process: The biggest difference between ceramic filter plates and previous filter media is their long service life, allowing for repeated use. After a period of operation, the filter plates, like other filter media, will become clogged. To restore their technical performance, after a period of operation, the equipment automatically enters the combined cleaning process under PLC control according to the set time and program. At this time, the ultrasonic vibrating plate set in the slurry tank vibrates at a frequency of about 30KHz, generating bubbles that undergo "cavitation" to "bombard" the attachments on the surface of the filter plate, promoting their detachment through mechanical means, achieving cleaning of the filter plate surface; acid washing (usually using dilute nitric acid) involves mixing acid with clean water (concentration 1-3%) and injecting it into the filter plate from the inside out to dissolve the clogging materials in the micropores of the filter plate. After combined cleaning, the filter plate is restored to its pre-filtration performance.

Product Advantages

- High vacuum degree (vacuum degree 0.09-0.098MPa), low moisture content in filter cake

- Filtrate solid content <50ppm can be reused, reducing emissions

- Compared with traditional filtration equipment, energy consumption is saved by about 90% or more, with low energy consumption and low operating costs

- Uses PLC and microcomputer combined automatic valve control, high degree of automation, reducing labor intensity

TC Vacuum Filter Press Parameter Table: (Partial Specifications)

Model Area (M2) | Number of Filter Plates (pieces) | Tank Volume (M3) | Installed Power (KW) | Operating Power (KW) | Main Machine Dimensions (M) | Filter Plate Specifications |

TC-1 | 12 | 0.2 | 4.5 | 3.5 | 1.4×1.4×1.9 | 1 M2/circle |

TC-4 | 24 | 0.8 | 5.5 | 4.5 | 1.7 ×2.2×2.0 | 2 M2/circle |

TC-6 | 36 | 1.1 | 8.0 | 7.0 | 2.0×2.2×2.0 | |

TC-9 | 36 | 1.9 | 8.5 | 7.5 | 3.1×2.8×2.6 | 3 M2/circle |

TC-12 | 48 | 2.6 | 9.0 | 8.0 | 3.4×2.8×2.6 | |

TC-15 | 60 | 2.9 | 9.0 | 8.0 | 3.7×2.8×2.6 | |

TC-21 | 84 | 3.9 | 15.5 | 14.5 | 4.3×2.85×2.6 | |

TC-24 | 96 | 4.3 | 15.5 | 14.5 | 4.6×2.85×2.6 | |

TC-30 | 120 | 5.2 | 19 | 18 | 5.2×2.85×2.6 | |

TC-36 | 144 | 6.1 | 19 | 18 | 5.8×2.85×2.6 | |

TC-45 | 180 | 7.4 | 26 | 25 | 6.7×2.85×2.6 | |

TC-40 | 120 | 7.0 | 23 | 22 | 5.2×3.2×3.0 | 4 M2/circle |

TC-48 | 144 | 8.2 | 24 | 23 | 5.8×3.2×3.0 | |

TC-60 | 180 | 10.0 | 39 | 38 | 6.9×3.3×3.0 | |

TC-80 | 240 | 14.5 | 39 | 38 | 8.4×3.3×3.0 | |

TC-40 | 96 | 5.8 | 26 | 25 | 4.9×3.3×3.1 | 5 M2/circle |

TC-45 | 108 | 6.0 | 26 | 25 | 5.2×3.3×3.1 | |

TC-50 | 120 | 6.9 | 26 | 25 | 5.5×3.3×3.1 | |

TC-55 | 132 | 7.5 | 33 | 32 | 5.8×3.3×3.1 | |

TC-60 | 144 | 8.1 | 33 | 32 | 6.1×3.3×3.1 | |

TC-100 | 240 | 12.7 | 47 | 46 | 8.5×3.3×3.1 | |

TC-78 | 156 | 12.7 | 39 | 38 | 6.4×3.7×3.3 | 6 M2/circle |

TC-96 | 192 | 15.1 | 57 | 56 | 7.3×3.7×3.3 | |

TC-120 | 240 | 18.3 | 57 | 56 | 8.5×3.7×3.3 | |

TC-96 | 120 | 25 | 90 | 80 | 6.73×5.9×4.78 | 12 M2/circle |

TC-120 | 150 | 30 | 110 | 100 | 7.53×5.9×4.78 | |

TC-144 | 180 | 35 | 110 | 100 | 8.57×5.9×4.78 | |

TC-168 | 210 | 40 | 110 | 100 | 9.37×5.9×4.78 | |

TC-192 | 240 | 45 | 130 | 120 | 10.2×5.9×4.78 |

Running Video

TC operation video

Contact Us

Contact E-mail

Contact Address

33 Wenzhou Street, Haiyang Economic Development Zone, Yantai, Shandong

Provide you with complete solid-liquid separation products and industry solutions

Committed to building strategic partnerships with users, user needs-oriented, in-depth study of industry characteristics, targeted optimization of product structure, focusing on user experience

Company establishment time

Technical center has more than 20 staff

Rich experience in filter design

Partners

How are we different from other suppliers?

At any time, we can provide customers with filter design solutions that meet the on-site process.

Rich industry experience

We are committed to providing a full range of solid-liquid separation products and solutions. With years of industry accumulation and experience, we have deep professional knowledge and technical strength. We are convinced that through our professional services and continuous innovation, we can help customers achieve greater success in the field of solid-liquid separation.

Wide range of product applications

Today, when environmental protection has increasingly become the focus of development, Yantai Nuclear One has always followed the pace of the industry, paid close attention to the latest developments in the filtration industry, and has deep involvement in many fields such as environmental protection, medicine, food, chemical industry, and mining.

Product customization

We always pay attention to customer needs, and can customize efficient filter design for customers at any time according to on-site process requirements. Our team pays attention to detail and strives for perfection to ensure that each filter can meet the unique needs of customers. At the same time, we provide end-to-end service support, from design, production to installation and commissioning, to protect the interests of customers in an all-round way.

Superior price-performance ratio

This source manufacturer has extraordinary strength, integrating R & D, manufacturing and sales, and has the ability to control the whole chain from the source to the terminal. In terms of cost performance, the manufacturer has made great efforts to provide high quality products at reasonable prices, and has won the trust and praise of customers.

Perfect service

We are committed to providing customers with a satisfactory service experience. No matter what problems you encounter, we will actively respond and solve them quickly. Our service team is professional and efficient, always paying attention to customer needs, ensuring that you are carefree in the process of using our products

Plant Equipment

According to the development of the filtration industry, we closely follow the new technologies and processes in the industry to ensure the high quality and high reliability of the products.

We are interested in our products.

Enter your contact information and we will contact you as soon as possible.

Quality Inspection

Rich experience in filter design, access to dozens of filter-related technology patents, ready to provide customers with on-site process to meet the filter design

Customer Visits

Provide you with complete solid-liquid separation products and industry solutions

Packaging Delivery

Committed to building strategic partnerships with users, user needs-oriented, in-depth study of industry characteristics, targeted optimization of product structure, focusing on user experience

Industry Solutions

Focus on environmental protection, medicine, food, chemical, mining and other enterprises, to provide perfect solid-liquid separation products and solutions

Hot Products

Expand the field and develop steadily. The company has gradually become a professional filter manufacturer integrating "Nuclear One" brand DU rubber belt vacuum filter, PBF mobile disc vacuum filter, TC ceramic filter, GP fixed disc filter, LX full-automatic centrifuge, HVPF full-automatic vertical filter press, DY belt press dewatering machine and its control system design and system debugging services.