Ceramic filter plate

A highly efficient separation device that uses filter cloth as the filtering medium and relies on vacuum negative pressure to achieve solid-liquid separation. This device has a simple structure, low manufacturing and operating costs, and is easy to maintain and operate.

Keyword:

Classification:

Product Display

The structural characteristics of ceramic vacuum filter plates mainly include

1. Porous ceramic matrix High purity ceramic materials such as alumina and silicon carbide are used to form a uniform microporous network (pore size 0.5-100 microns) through sintering, achieving high-precision filtration.

2. Gradient pore design The surface layer is a dense fine pore layer (intercepting impurities), and the bottom layer is a coarse pore support layer (enhancing mechanical strength and reducing fluid resistance).

3. Honeycomb or flat structure Common honeycomb multi-channel design increases the effective filtration area; Edge sealing treatment ensures vacuum adsorption stability.

4. High strength support frame Built in metal or ceramic reinforcement ribs, resistant to compression and bending (strength 10-50MPa), suitable for high-pressure backwashing and vacuum negative pressure environments.

5. Modular connection interface Standardized flange or slot design for quick installation and replacement.. Structural mcore: gradient pores+high-strength support, balancing filtration accuracy, anti clogging ability and durability, suitable for harsh working conditions such as metallurgy and chemical industry..

Ceramic filter plate model

No. | Model | Overall dimension | ||||

L1 | L2 | L3 | B | C | ||

1 | 2m/12 | 225 | 165 | 380 | 320 | 25 |

2 | 3m/12 | 295 | 239 | 485 | 395 | 25/30 |

3 | 4m/12 | 338 | 276 | 555 | 441 | 30 |

4 | 5m/12 | 300 | 240 | 568 | 550 | 35 |

5 | 6m/12 | 294 | 235 | 603 | 619 | 32 |

6 | 12m/12 | / | 430 | 777.3 | 822 | 36 |

Describe : L1=Lower width of filter fan L2=Installment Center Distance L3=Width on the filter fan plate B=Height of filter fan plate C=Thickness of filter fan plate Customization can also be made according to the required size. | ||||||

Running Video

Contact Us

Contact E-mail

Contact Address

33 Wenzhou Street, Haiyang Economic Development Zone, Yantai, Shandong

Provide you with complete solid-liquid separation products and industry solutions

Committed to building strategic partnerships with users, user needs-oriented, in-depth study of industry characteristics, targeted optimization of product structure, focusing on user experience

Company establishment time

Technical center has more than 20 staff

Rich experience in filter design

Partners

How are we different from other suppliers?

At any time, we can provide customers with filter design solutions that meet the on-site process.

Rich industry experience

We are committed to providing a full range of solid-liquid separation products and solutions. With years of industry accumulation and experience, we have deep professional knowledge and technical strength. We are convinced that through our professional services and continuous innovation, we can help customers achieve greater success in the field of solid-liquid separation.

Wide range of product applications

Today, when environmental protection has increasingly become the focus of development, Yantai Nuclear One has always followed the pace of the industry, paid close attention to the latest developments in the filtration industry, and has deep involvement in many fields such as environmental protection, medicine, food, chemical industry, and mining.

Product customization

We always pay attention to customer needs, and can customize efficient filter design for customers at any time according to on-site process requirements. Our team pays attention to detail and strives for perfection to ensure that each filter can meet the unique needs of customers. At the same time, we provide end-to-end service support, from design, production to installation and commissioning, to protect the interests of customers in an all-round way.

Superior price-performance ratio

This source manufacturer has extraordinary strength, integrating R & D, manufacturing and sales, and has the ability to control the whole chain from the source to the terminal. In terms of cost performance, the manufacturer has made great efforts to provide high quality products at reasonable prices, and has won the trust and praise of customers.

Perfect service

We are committed to providing customers with a satisfactory service experience. No matter what problems you encounter, we will actively respond and solve them quickly. Our service team is professional and efficient, always paying attention to customer needs, ensuring that you are carefree in the process of using our products

Plant Equipment

According to the development of the filtration industry, we closely follow the new technologies and processes in the industry to ensure the high quality and high reliability of the products.

We are interested in our products.

Enter your contact information and we will contact you as soon as possible.

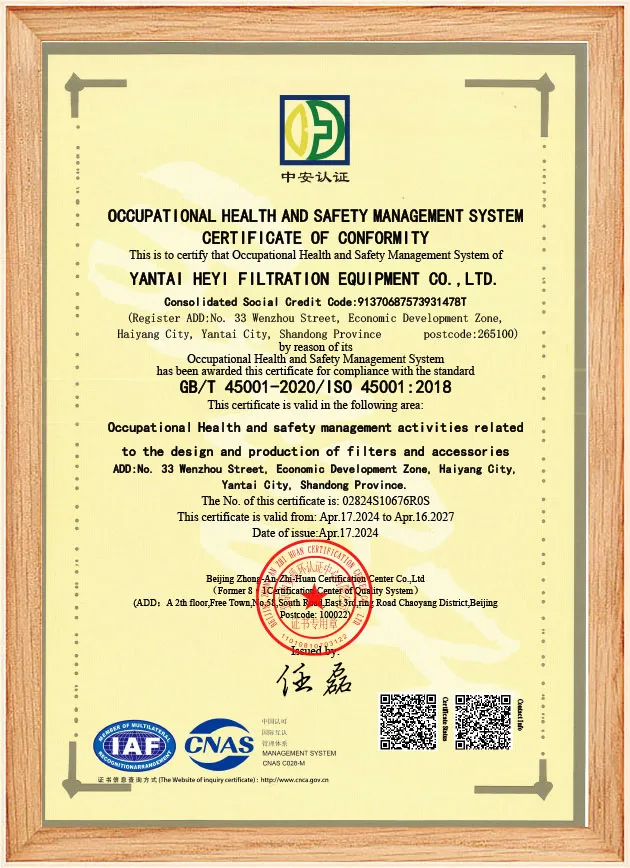

Quality Inspection

Rich experience in filter design, access to dozens of filter-related technology patents, ready to provide customers with on-site process to meet the filter design

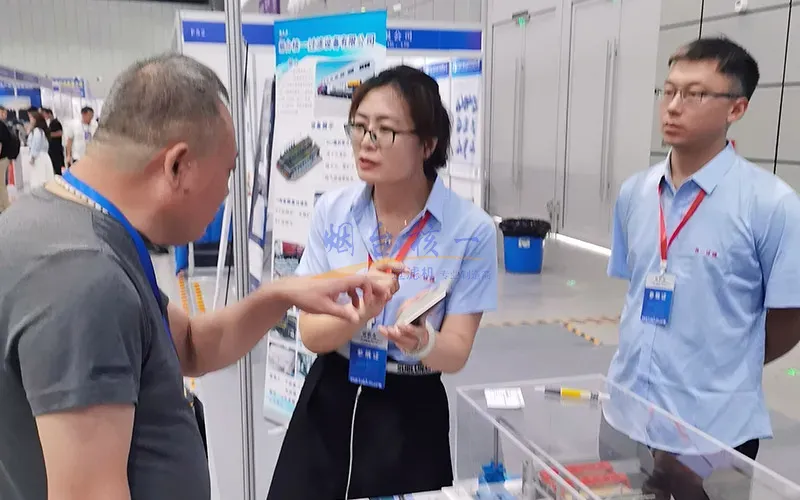

Customer Visits

Provide you with complete solid-liquid separation products and industry solutions

Packaging Delivery

Committed to building strategic partnerships with users, user needs-oriented, in-depth study of industry characteristics, targeted optimization of product structure, focusing on user experience

Industry Solutions

Focus on environmental protection, medicine, food, chemical, mining and other enterprises, to provide perfect solid-liquid separation products and solutions

Hot Products

Expand the field and develop steadily. The company has gradually become a professional filter manufacturer integrating "Nuclear One" brand DU rubber belt vacuum filter, PBF mobile disc vacuum filter, TC ceramic filter, GP fixed disc filter, LX full-automatic centrifuge, HVPF full-automatic vertical filter press, DY belt press dewatering machine and its control system design and system debugging services.