Thickening machine

It has the function of concentration and clarification, and achieves solid-liquid separation based on the principle of gravitational sedimentation. It is divided into two types: central drive and peripheral drive.

Keyword:

Classification:

Product Display

Product Introduction

The thickener (also known as a concentrator) has the functions of concentration and clarification, and it achieves solid-liquid separation based on the principle of gravity sedimentation. It is divided into two types: center-driven and peripheral-driven.

The center-driven thickener mainly consists of a circular pool, rakes, and a drive mechanism. The bottom of the pool is a gently sloping conical shape, with an inclination angle of 6° to 12° relative to the horizontal plane. The pool is generally made of concrete, and smaller diameters can also be made of welded steel plates. There is an annular overflow tank at the upper edge of the inner wall of the pool for discharging overflow. The vertical shaft located in the center of the pool is connected to the rake mechanism. The rake mechanism consists of rake arms, rake teeth, and reinforcing tie rods. Two radially arranged rake arms are perpendicular to each other in a cross shape. To ensure that all the concentrated product settled at the bottom of the pool is discharged through the discharge port, the rake teeth are installed on the rake arms at an angle of about 30°.

Product Features

(1) An additional degassing tank is added to avoid solid particles adhering to bubbles, resembling a "parachute" sedimentation phenomenon.

(2) The feed pipe is located below the liquid surface to prevent gas from being brought in during feeding.

(3) The feed sleeve is lowered and equipped with a receiving plate, allowing the incoming slurry to fall evenly and smoothly, effectively preventing the phenomenon of turbulence caused by residual pressure during feeding;

(4) An internal overflow weir is added to ensure that materials flow according to the specified travel, preventing the "short-circuit" phenomenon;

(5) The overflow weir is changed to a serrated shape, improving the suction phenomenon caused by uneven drainage due to the overflow weir not being level;

(6) The rake teeth are changed from a linear diagonal shape to a curved shape, allowing the slurry to not only move towards the center rake but also providing a force that "presses" towards the center, resulting in a higher concentration of the bottom flow of the discharged ore, thereby increasing the processing capacity.

Running Video

Contact Us

Contact E-mail

Contact Address

33 Wenzhou Street, Haiyang Economic Development Zone, Yantai, Shandong

Provide you with complete solid-liquid separation products and industry solutions

Committed to building strategic partnerships with users, user needs-oriented, in-depth study of industry characteristics, targeted optimization of product structure, focusing on user experience

Company establishment time

Technical center has more than 20 staff

Rich experience in filter design

Partners

How are we different from other suppliers?

At any time, we can provide customers with filter design solutions that meet the on-site process.

Rich industry experience

We are committed to providing a full range of solid-liquid separation products and solutions. With years of industry accumulation and experience, we have deep professional knowledge and technical strength. We are convinced that through our professional services and continuous innovation, we can help customers achieve greater success in the field of solid-liquid separation.

Wide range of product applications

Today, when environmental protection has increasingly become the focus of development, Yantai Nuclear One has always followed the pace of the industry, paid close attention to the latest developments in the filtration industry, and has deep involvement in many fields such as environmental protection, medicine, food, chemical industry, and mining.

Product customization

We always pay attention to customer needs, and can customize efficient filter design for customers at any time according to on-site process requirements. Our team pays attention to detail and strives for perfection to ensure that each filter can meet the unique needs of customers. At the same time, we provide end-to-end service support, from design, production to installation and commissioning, to protect the interests of customers in an all-round way.

Superior price-performance ratio

This source manufacturer has extraordinary strength, integrating R & D, manufacturing and sales, and has the ability to control the whole chain from the source to the terminal. In terms of cost performance, the manufacturer has made great efforts to provide high quality products at reasonable prices, and has won the trust and praise of customers.

Perfect service

We are committed to providing customers with a satisfactory service experience. No matter what problems you encounter, we will actively respond and solve them quickly. Our service team is professional and efficient, always paying attention to customer needs, ensuring that you are carefree in the process of using our products

Plant Equipment

According to the development of the filtration industry, we closely follow the new technologies and processes in the industry to ensure the high quality and high reliability of the products.

We are interested in our products.

Enter your contact information and we will contact you as soon as possible.

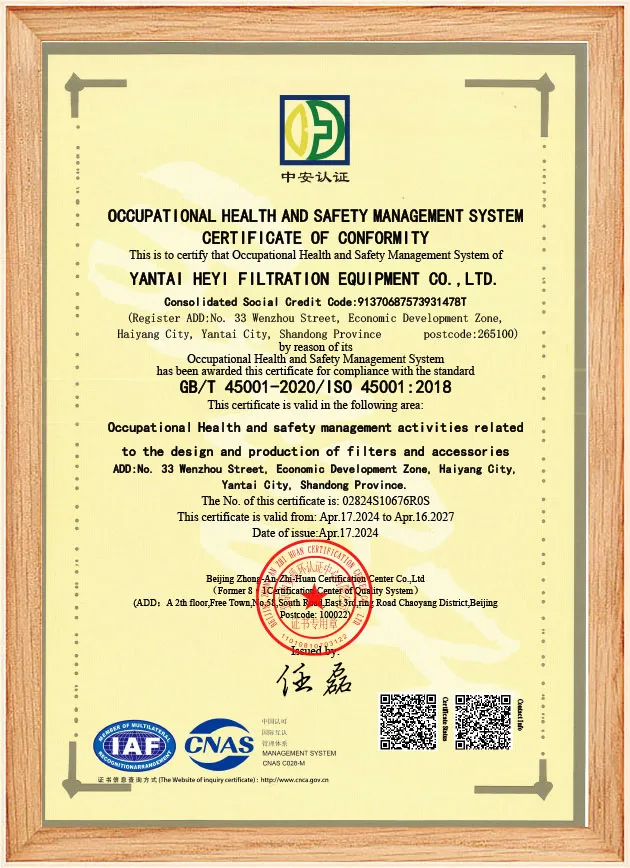

Quality Inspection

Rich experience in filter design, access to dozens of filter-related technology patents, ready to provide customers with on-site process to meet the filter design

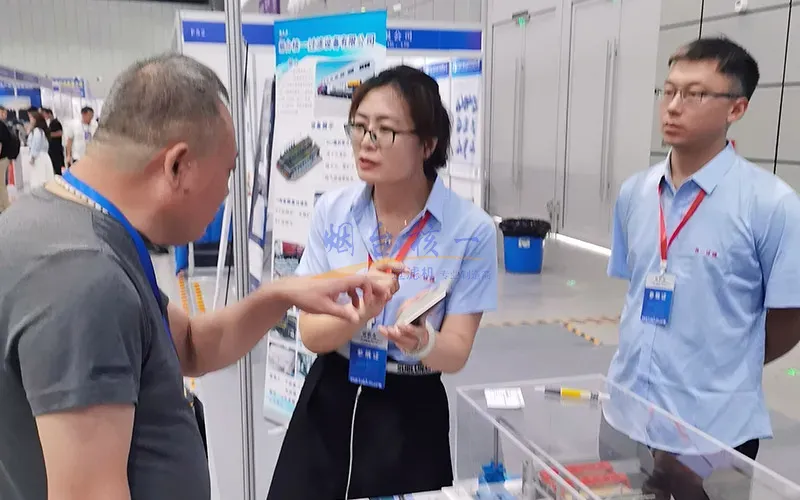

Customer Visits

Provide you with complete solid-liquid separation products and industry solutions

Packaging Delivery

Committed to building strategic partnerships with users, user needs-oriented, in-depth study of industry characteristics, targeted optimization of product structure, focusing on user experience

Industry Solutions

Focus on environmental protection, medicine, food, chemical, mining and other enterprises, to provide perfect solid-liquid separation products and solutions

Hot Products

Expand the field and develop steadily. The company has gradually become a professional filter manufacturer integrating "Nuclear One" brand DU rubber belt vacuum filter, PBF mobile disc vacuum filter, TC ceramic filter, GP fixed disc filter, LX full-automatic centrifuge, HVPF full-automatic vertical filter press, DY belt press dewatering machine and its control system design and system debugging services.