Vertical filter press

The equipment utilizes the pressure of the pump, the gravity of the material, and the squeezing action of the rubber diaphragm to quickly filter the slurry through the filter cloth, thereby achieving efficient solid-liquid separation.

Keyword:

Classification:

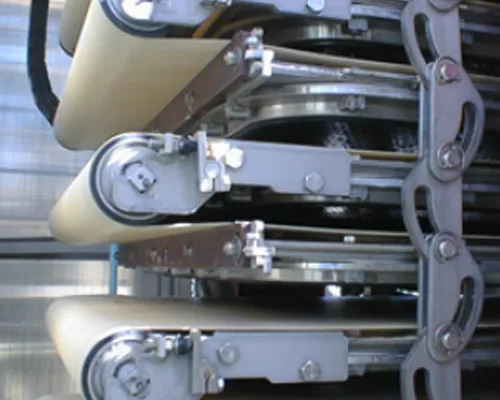

Product Display

Product Overview

The HVPF vertical fully automatic filter press is a new, efficient, energy-saving, and environmentally friendly solid-liquid separation equipment developed by our company. The equipment uses the pressure of the pump, the gravity of the material, and the squeezing action of the rubber diaphragm to quickly filter the slurry through the filter cloth, thus achieving efficient solid-liquid separation.

★ Horizontal filtration of filter plates, multi-cylinder synchronous up and down operation, hydraulic cylinder self-guiding, compact structure, and novel design;

★ The entire operation process of filtration, squeezing, washing, drying, cake unloading, and filter cloth regeneration is automatically and continuously completed;

★ The squeezing pressure can reach 2.0MPa, which is particularly effective for various viscous fine materials and occasions with low moisture requirements for filter cakes;

★ The equipment operates using fully hydraulic control, ensuring smooth, reliable operation with a high safety factor;

★ Uses PLC + touch screen + automatic valve for fully automatic control, making operation simple and highly automated;

★ Low moisture content of filter cakes, large production capacity, and work efficiency several times or even more than traditional filter presses;

Product Features

The HVPF filter press is a high-efficiency, energy-saving, and highly automated solid-liquid separation equipment. The equipment utilizes the pressure of the pump,

high-pressure hot air, and gas pressure to create a pressure difference on both sides of the filter cloth, thus achieving efficient solid-liquid separation.

Features:

« Stacked structure of filter plates with guiding devices for smooth operation;

« The entire operation process of filtration, drying, unloading, and filter cloth regeneration can be continuously and automatically completed;

« Single-layer independent circulation of filter cloth for high efficiency;

« High-pressure hot air drying, resulting in low moisture content of filter cakes;

« No diaphragm, no sealing strip design, resulting in low failure rate;

« Compact structure, occupying a small area;

« Single-sided unloading, requiring fewer supporting devices;

« Filter plate layers can be independently disassembled and reused, convenient for use.

The filter press is widely used in metallurgy, mining, chemical industry, coal chemical industry, titanium dioxide, papermaking, food,

pharmaceuticals, and many other industries. It is a replacement product and technology for traditional filtration and filter press equipment.

Equipment Selection Table 1

| Model | Filtration Area | Dimensions | Number of Filter Layers | Volume m | Weight | Hydraulic Power | Filter Plate Specifications | Filter Cloth Width |

| (m²) | (L*W*H)(m) | (Layers) | (H=45mm) | (T) | (KW) | (mm | (m) | |

| HVPF-1 | 1 | 25×1.5×20 | 2 | 0.05 | 8 | 7.5 | 1000X550 | 0.7 |

| HVPF-2 | 2 | 25×1.5×22 | 4 | 0.09 | 9 | 7.5 | ||

| HVPF-3 | 3 | 3.5×25×22 | 2 | 0.16 | 14 | 11 | 1750X900 | 1.05 |

| HVPF-4 | 4 | 3.5×25×23 | 4 | 27 | 15 | 11 | ||

| HVPF-9 | 9 | 3.5×25×25 | 6 | 0.41 | 16 | 11 | ||

| HVPF-12 | 12 | 3.5×25×27 | 8 | 0.54 | 17 | 11 | ||

| HVPF-15 | 15 | 3.5×25×29 | 10 | 0.68 | 18 | 11 | ||

| HVPF-18 | 18 | 3.5×25×3.1 | 12 | 0.81 | 19 | 11 | ||

| HVPF-21 | 21 | 3.5×25×3.3 | 14 | 95 | 21 | 11 | ||

| HVPF-24 | 24 | 3.5×25×3.4 | 16 | 1.08 | 22 | 11 | ||

| HVPF-27 | 27 | 3.5×2.5×36 | 18 | 1.22 | 23 | 11 |

Equipment Selection Table 2

| Model | Filtration Area | Dimensions | Number of Filter Layers | Volume m | Weight | Hydraulic Power | Filter Plate Specifications | Filter Cloth Width |

| (m²) | (L*W*H)(m) | (Layers) | (H=45mm) | (T) | (KW) | (mm | (m) | |

| HVPF-15 | 15 | 5.1×3.7×3.3 | 6 | 0.68 | 37 | 22 | 2500×1020 | 1.15 |

| HVPF-20 | 20 | 5.1×3.7×3.6 | 8 | 0.9 | 39 | 22 | ||

| HVPF-25 | 25 | 5.1×3.7×39 | 10 | 1.13 | 42 | 22 | ||

| HVPF-30 | 30 | 5.1×3.7×4.2 | 12 | 1.35 | 43 | 22 | ||

| HVPF-35 | 35 | 5.1×3.7×4.5 | 14 | 1.58 | 44 | 22 | ||

| HVPF-40 | 40 | 5.1×3.7×4.8 | 16 | 1.8 | 45 | 22 | ||

| HVPF-45 | 45 | 5.1×3.7×5. | 18 | 2.03 | 46 | 22 | ||

| HVPF-50 | 50 | 5.1×3.7×5.4 | 20 | 2.25 | 48 | 22 |

| Model | Filtration Area | Dimensions | Number of Filter Layers | Volume m | Weight | Hydraulic Power | Filter Plate Specifications | Filter Cloth Width |

| (m²) | (L*W*H)(m) | (Layers) | (H=45mm) | (T) | (KW) | (mm | (m) | |

| HVPF-60 | 60 | 69×4.5×5.4 | 10 | 270 | 97 | 37 | 4010×1500 | 1.7 |

| HVPF-72 | 72 | 6.9×4.5×5.8 | 12 | 324 | 100 | 37 | ||

| HVPF-84 | 84 | 69×45×6.2 | 14 | 3.78 | 104 | 37 | ||

| HVPF-96 | 96 | 6.9×4.5×6.5 | 16 | 4.32 | 110 | 37 | ||

| HVPF-108 | 108 | 6.9×4.5×6.9 | 18 | 4.86 | 112 | 37 | ||

| HVPF-120 | 120 | 6.9×4.5×7.2 | 20 | 5.4 | 118 | 37 | ||

| HVPF-132 | 132 | 6.9×4.5×7.6 | 22 | 5.94 | 120 | 37 | ||

| HVPF-144 | 144 | 6.9×4.5×79 | 24 | 6.48 | 123 | 37 | ||

| HVPF-156 | 156 | 69×4.5×8.3 | 26 | 7.02 | 126 | 37 | ||

| HVPF-168 | 168 | 6.9×45×8.6 | 28 | 7.56 | 130 | 37 | ||

| HVPF-144 | 144 | 9.2×5.5×6.8 | 18 | 6.48 | 142 | 67 | 6020×1500 | 1.7 |

| HVPF-162 | 162 | 9.2×5.5×7.2 | 18 | 7.29 | 147 | 67 | ||

| HVPF-180 | 180 | 9.2×5.5×7.5 | 20 | 8.1 | 150 | 67 | ||

| HVPF-198 | 198 | 9.2×5.5×7.8 | 22 | 8.91 | 160 | 67 | ||

| HVPF-216 | 216 | 9.2×5.5×8.2 | 24 | 9.72 | 166 | 67 | ||

| HVPF-234 | 234 | 9.2×5.5×8.5 | 26 | 10.53 | 172 | 67 | ||

| HVPF-252 | 252 | 9.2×5.5×8.8 | 28 | 11.34 | 180 | 67 | ||

| HVPF-270 | 270 | 9.2×5.5×9.2 | 30 | 12.15 | 190 | 67 |

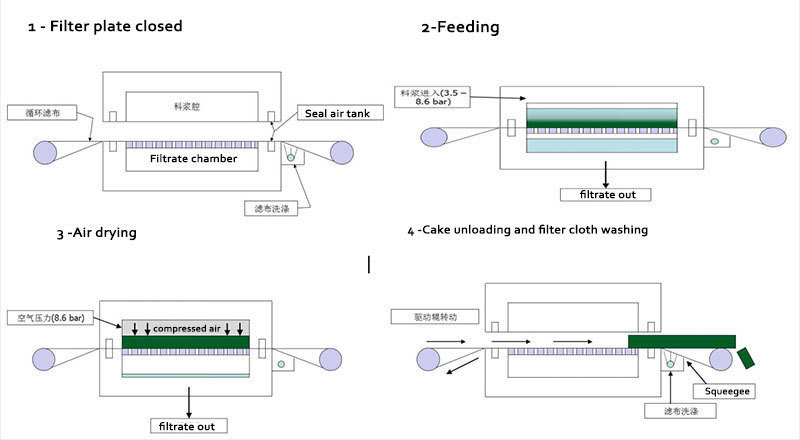

Filter press workflow diagram

Feature 1, Hydraulic cylinder structure

Four-cylinder synchronous guiding technology

The upper pressing plate of the equipment is cleverly driven by the hydraulic cylinders on the four sides to move up and down, and the hydraulic cylinders can achieve precise synchronization with good lubrication performance; it avoids the shortcomings of the domestic four-column structure, which has poor lubrication performance due to the separate four-column synchronization and the separate lifting of the hydraulic cylinders, leading to complex equipment structure, making it easy for external forces to jam the four-column guiding columns and break the lifting hydraulic cylinders, resulting in unreasonable design and high failure rates.

Feature 2, Hydraulic control technology

Series and parallel synchronization technology

Control methods for hydraulic cylinder synchronization:

1. Mechanical synchronization (rigid connection). (Cannot bear large loads).

2. Flow diversion and collection valve control synchronization, synchronization accuracy 1%-2%.

3. Synchronous motor (or gear diverter) control synchronization, synchronization accuracy 1.5%-2.5%.

4. Throttle valve control synchronization (load balancing), synchronization accuracy is poor.

Feature 3, Automatic correction

Three-point positioning correction technology

Using hydraulic cylinders to push the correction roller to deflect at a certain angle to correct the deviation of the filter belt, with high sensitivity; during the operation of the filter cloth, it touches the proximity switches on both sides, and the proximity switch signal is transmitted to the control system, causing the hydraulic cylinder to start actions according to preset settings. The hydraulic cylinder only needs to move a small displacement to achieve a significant correction effect, and the hydraulic cylinders use domestic brand products, ensuring reliable and stable quality. There are correction signal detectors on both sides of the filter cloth, and a filter cloth position alarm is used in conjunction to ensure normal correction of the filter cloth.

Feature 4, Control system

Simple integrated control

A professional automated production line has formed a specialized supporting system from processing and manufacturing to product service. It provides customers with faster and higher quality products and training services.

The entire system is fully PLC controlled, with monitoring designed for the opening and closing of the filter plate group, the operation of the filter cloth, deviation, and various process parameters. The working modes at each stage can be manually controlled or automatically controlled, with a stage timer designed to achieve work cycle counting. It uses a touch screen and PLC for digital communication, displaying the entire process flow and having the ability to trace working parameters, employing a programmable controller with flexible program design to ensure the system is reliable and accurate.

Feature 5, Automatic discharge

Non-sticking discharge

The self-adjusting scraper discharge device can automatically adjust the scraper angle according to the position of the guide roller, allowing the scraper to automatically fit with the filter cloth and the guide roller, achieving the best discharge effect.

Feature 6, Small footprint, simple structure, easy to enclose

The tower-type filter press occupies a smaller area than traditional filter presses and has a lower height. It is easy to maintain.

Each intermediate module includes a cleaning system, which consists of a water receiving tray, filtrate block, spray washing pipe, nozzle for cake unloading, and simultaneous washing of the filter cloth without additional cycle time for cleaning.

Running Video

Contact Us

Contact E-mail

Contact Address

33 Wenzhou Street, Haiyang Economic Development Zone, Yantai, Shandong

Provide you with complete solid-liquid separation products and industry solutions

Committed to building strategic partnerships with users, user needs-oriented, in-depth study of industry characteristics, targeted optimization of product structure, focusing on user experience

Company establishment time

Technical center has more than 20 staff

Rich experience in filter design

Partners

How are we different from other suppliers?

At any time, we can provide customers with filter design solutions that meet the on-site process.

Rich industry experience

We are committed to providing a full range of solid-liquid separation products and solutions. With years of industry accumulation and experience, we have deep professional knowledge and technical strength. We are convinced that through our professional services and continuous innovation, we can help customers achieve greater success in the field of solid-liquid separation.

Wide range of product applications

Today, when environmental protection has increasingly become the focus of development, Yantai Nuclear One has always followed the pace of the industry, paid close attention to the latest developments in the filtration industry, and has deep involvement in many fields such as environmental protection, medicine, food, chemical industry, and mining.

Product customization

We always pay attention to customer needs, and can customize efficient filter design for customers at any time according to on-site process requirements. Our team pays attention to detail and strives for perfection to ensure that each filter can meet the unique needs of customers. At the same time, we provide end-to-end service support, from design, production to installation and commissioning, to protect the interests of customers in an all-round way.

Superior price-performance ratio

This source manufacturer has extraordinary strength, integrating R & D, manufacturing and sales, and has the ability to control the whole chain from the source to the terminal. In terms of cost performance, the manufacturer has made great efforts to provide high quality products at reasonable prices, and has won the trust and praise of customers.

Perfect service

We are committed to providing customers with a satisfactory service experience. No matter what problems you encounter, we will actively respond and solve them quickly. Our service team is professional and efficient, always paying attention to customer needs, ensuring that you are carefree in the process of using our products

Plant Equipment

According to the development of the filtration industry, we closely follow the new technologies and processes in the industry to ensure the high quality and high reliability of the products.

We are interested in our products.

Enter your contact information and we will contact you as soon as possible.

Quality Inspection

Rich experience in filter design, access to dozens of filter-related technology patents, ready to provide customers with on-site process to meet the filter design

Customer Visits

Provide you with complete solid-liquid separation products and industry solutions

Packaging Delivery

Committed to building strategic partnerships with users, user needs-oriented, in-depth study of industry characteristics, targeted optimization of product structure, focusing on user experience

Industry Solutions

Focus on environmental protection, medicine, food, chemical, mining and other enterprises, to provide perfect solid-liquid separation products and solutions

Hot Products

Expand the field and develop steadily. The company has gradually become a professional filter manufacturer integrating "Nuclear One" brand DU rubber belt vacuum filter, PBF mobile disc vacuum filter, TC ceramic filter, GP fixed disc filter, LX full-automatic centrifuge, HVPF full-automatic vertical filter press, DY belt press dewatering machine and its control system design and system debugging services.