Vacuum pump

By changing the structural materials, it can also be used to absorb corrosive gases or corrosive liquids as working fluids.

Keyword:

Classification:

Product Display

Introduction to Vacuum Pumps

The 2BEA/C series water ring vacuum pumps and compressors are typically used to extract gases that do not contain solid particles, are insoluble in water, and are non-corrosive, in order to create a vacuum and pressure in a closed container. By changing the structural materials, they can also be used to extract corrosive gases or corrosive liquids as working fluids. They are widely used in industries such as papermaking, chemical, petrochemical, light industry, pharmaceuticals, food, metallurgy, building materials, electrical appliances, coal, metal mining, and fertilizers.

Product Advantages

This series of pumps adopts a single-stage single-action structure, which has the advantages of simple structure, convenient maintenance, reliable operation, and high energy efficiency, and can adapt to harsh working conditions such as large drainage volumes and impact fluctuations. We have optimized the design of key components such as the distribution plate, impeller, and pump shaft, simplifying the structure, improving performance, and achieving energy savings. The impeller is made of ductile iron or welded, with blades formed by a single stamping process, ensuring a reasonable profile; all wheels are processed to fundamentally solve the dynamic balance problem. The impeller and pump shaft are fitted with a thermal interference fit, ensuring reliable performance and smooth operation. After welding, the impeller undergoes overall heat treatment, giving the blades good toughness and fundamentally ensuring the impact resistance and bending resistance of the blades, allowing them to adapt to harsh working conditions at the load impact wave separation point.

2BEA Technical Parameter Table

Model | Minimum Inlet Pressure hPa | Pump Speed r/min | Maximum Air Volume m³/min | Motor Power KW | Transmission Type | Motor Voltage | Inlet Diameter mm | Outlet Diameter mm |

2BEA-252-0 | 33 | 565 | 20 | 30 | Belt | 380V | 150 | 150 |

590 | 22 | 30 | Coupling | |||||

660 | 25 | 30 | Belt | |||||

740 | 28 | 45 | Coupling | |||||

820 | 30 | 55 | Belt | |||||

880 | 33 | 75 | Belt | |||||

2BEA-253-0 | 33 | 565 | 28 | 45 | Belt | 380V | 150 | 150 |

590 | 30 | 45 | Coupling | |||||

660 | 35 | 55 | Belt | |||||

740 | 39 | 75 | Coupling | |||||

820 | 43 | 90 | Belt | |||||

880 | 47 | 90 | Belt | |||||

2BEA-303-0 | 33 | 472 | 43 | 55 | Belt | 380V | 200 | 200 |

520 | 45 | 75 | Belt | |||||

530 | 48 | 75 | Belt | |||||

590 | 52 | 75 | Coupling | |||||

660 | 58 | 90 | Belt | |||||

740 | 60 | 110 | Coupling | |||||

2BEA-353-0 | 33 | 390 | 55 | 75 | Belt | 380V | 250 | 250 |

415 | 58 | 90 | Belt | |||||

464 | 65 | 110 | Belt | |||||

520 | 72 | 132 | Belt | |||||

590 | 81 | 160 | Coupling | |||||

2BEA-403-0 | 33 | 330 | 78 | 132 | Belt | 380V | 300 | 300 |

372 | 85 | 160 | Belt | |||||

420 | 97 | 185 | Belt | |||||

472 | 110 | 200 | Belt | |||||

530 | 122 | 250 | Belt | |||||

2BEA-355-1 | 160 | 372 | 61 | 90 | Belt | 380V | 250 | 250 |

420 | 71 | 110 | Belt | 380V | ||||

472 | 79 | 110 | Belt | 380V | ||||

500 | 83 | 132 | Belt | 380V | ||||

530 | 88 | 132 | Belt | 380V | ||||

590 | 95 | 160 | Coupling | 380V | ||||

2BEA-405-1 | 160 | 330 | 93 | 132 | Belt or Reducer | 380V | 300 | 300 |

372 | 106 | 160 | 380V | |||||

420 | 119 | 182 | 380V | |||||

472 | 130 | 220 | 380V | |||||

530 | 141 | 280 | 380V | |||||

2BEA-505-1 | 160 | 266 | 121 | 160 | Belt or Reducer | 380V | 350 | 350 |

298 | 139 | 185 | 380V | |||||

330 | 153 | 220 | 380V | |||||

372 | 169 | 250 | 6KV | |||||

420 | 186 | 315 | 6KV | |||||

2BEA-605-1 | 160 | 220 | 168 | 220 | Reducer | 6KV | 400 | 400 |

236 | 181 | 250 | 6KV | |||||

246 | 188 | 280 | 6KV | |||||

266 | 206 | 280 | 6KV | |||||

276 | 210 | 315 | 6KV | |||||

298 | 228 | 355 | 6KV | |||||

312 | 234 | 355 | 6KV | |||||

2BEA-705-1 | 160 | 197 | 259 | 355 | Reducer | 6KV or 10KV | 500 | 500 |

| 220 | 286 | 400 | ||||||

| 246 | 318 | 450 | ||||||

| 266 | 342 | 500 | ||||||

| 276 | 352 | 560 |

2BEC Technical Parameter Table

Model | Minimum Inlet Pressure hPa | Pump Speed r/min | Maximum Air Volume | Motor Power KW | Transmission Type | Motor Voltage | Inlet Diameter mm | Outlet Diameter mm |

m³/min | ||||||||

2BEC-400-1 | 160 | 300 | 68 | 75 | Belt | 380V | 300 | 300 |

323 | 80 | 90 | Reducer or Belt | |||||

367 | 85 | 110 | ||||||

393 | 92 | 110 | ||||||

449 | 110 | 132 | ||||||

2BEC-420-1 | 160 | 300 | 90 | 110 | Reducer or Belt | 380V | 300 | 300 |

330 | 110 | 132 | ||||||

360 | 120 | 132 | ||||||

390 | 126 | 160 | ||||||

420 | 134 | 185 | ||||||

2BEC-500-1 | 160 | 242 | 125 | 160 | Reducer or Belt | 380V | 350 | 350 |

266 | 145 | 185 | 380V | |||||

294 | 165 | 200 | 380V | |||||

336 | 190 | 250 | 6KV | |||||

372 | 210 | 280 | 6KV | |||||

2BEC-520-1 | 160 | 236 | 150 | 185 | Reducer or Belt | 380V | 350 | 350 |

266 | 165 | 200 | 6KV | |||||

294 | 205 | 250 | 380V | |||||

336 | 235 | 280 | 380V | |||||

372 | 250 | 315 | 380V | |||||

2BEC-600-1 | 160 | 200 | 180 | 185 | Reducer | 380V | 400 | 400 |

236 | 210 | 250 | 6KV | |||||

266 | 240 | 280 | 6KV | |||||

294 | 260 | 315 | 6KV | |||||

336 | 285 | 350 | 6KV | |||||

2BEC-620-1 | 160 | 200 | 220 | 220 | Reducer | 6KV | 400 | 400 |

236 | 255 | 280 | ||||||

266 | 290 | 350 | ||||||

294 | 320 | 400 | ||||||

336 | 360 | 450 | ||||||

2BEC-670-1 | 160 | 210 | 300 | 315 | Reducer | 6KV | 500 | 500 |

240 | 345 | 400 | ||||||

270 | 380 | 450 | ||||||

300 | 410 | 560 | ||||||

330 | 450 | 630 | ||||||

370 | 510 | 800 | ||||||

2BEC-720-1 | 160 | 210 | 400 | 450 | Reducer | 6KV | 500 | 500 |

240 | 450 | 560 | ||||||

270 | 500 | 630 | ||||||

300 | 560 | 710 | ||||||

340 | 620 | 900 | ||||||

2BEC-800-1 | 160 | 190 | 513 | 560 | Reducer | 6KV or 10KV | 600 | 600 |

210 | 562 | 630 | ||||||

240 | 630 | 800 | ||||||

270 | 710 | 900 | ||||||

300 | 790 | 1120 | ||||||

2BEC-1000-1 | 160 | 170 | 850 | 900 | Reducer | 6KV or 10KV | 700 | 700 |

190 | 920 | 1120 | ||||||

210 | 1000 | 1250 | ||||||

225 | 1100 | 1600 | ||||||

240 | 1120 | 1800 |

Running Video

Contact Us

Contact E-mail

Contact Address

33 Wenzhou Street, Haiyang Economic Development Zone, Yantai, Shandong

Provide you with complete solid-liquid separation products and industry solutions

Committed to building strategic partnerships with users, user needs-oriented, in-depth study of industry characteristics, targeted optimization of product structure, focusing on user experience

Company establishment time

Technical center has more than 20 staff

Rich experience in filter design

Partners

How are we different from other suppliers?

At any time, we can provide customers with filter design solutions that meet the on-site process.

Rich industry experience

We are committed to providing a full range of solid-liquid separation products and solutions. With years of industry accumulation and experience, we have deep professional knowledge and technical strength. We are convinced that through our professional services and continuous innovation, we can help customers achieve greater success in the field of solid-liquid separation.

Wide range of product applications

Today, when environmental protection has increasingly become the focus of development, Yantai Nuclear One has always followed the pace of the industry, paid close attention to the latest developments in the filtration industry, and has deep involvement in many fields such as environmental protection, medicine, food, chemical industry, and mining.

Product customization

We always pay attention to customer needs, and can customize efficient filter design for customers at any time according to on-site process requirements. Our team pays attention to detail and strives for perfection to ensure that each filter can meet the unique needs of customers. At the same time, we provide end-to-end service support, from design, production to installation and commissioning, to protect the interests of customers in an all-round way.

Superior price-performance ratio

This source manufacturer has extraordinary strength, integrating R & D, manufacturing and sales, and has the ability to control the whole chain from the source to the terminal. In terms of cost performance, the manufacturer has made great efforts to provide high quality products at reasonable prices, and has won the trust and praise of customers.

Perfect service

We are committed to providing customers with a satisfactory service experience. No matter what problems you encounter, we will actively respond and solve them quickly. Our service team is professional and efficient, always paying attention to customer needs, ensuring that you are carefree in the process of using our products

Plant Equipment

According to the development of the filtration industry, we closely follow the new technologies and processes in the industry to ensure the high quality and high reliability of the products.

We are interested in our products.

Enter your contact information and we will contact you as soon as possible.

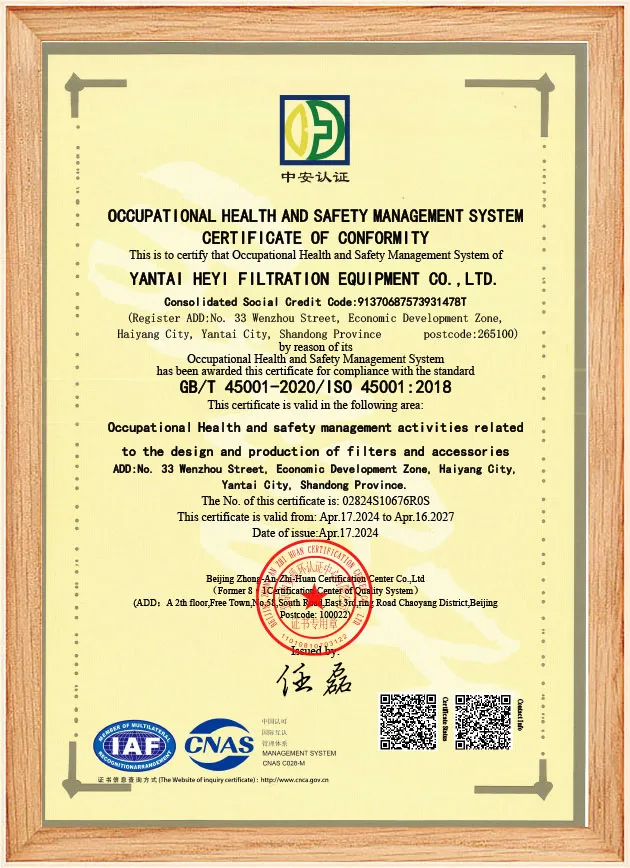

Quality Inspection

Rich experience in filter design, access to dozens of filter-related technology patents, ready to provide customers with on-site process to meet the filter design

Customer Visits

Provide you with complete solid-liquid separation products and industry solutions

Packaging Delivery

Committed to building strategic partnerships with users, user needs-oriented, in-depth study of industry characteristics, targeted optimization of product structure, focusing on user experience

Industry Solutions

Focus on environmental protection, medicine, food, chemical, mining and other enterprises, to provide perfect solid-liquid separation products and solutions

Hot Products

Expand the field and develop steadily. The company has gradually become a professional filter manufacturer integrating "Nuclear One" brand DU rubber belt vacuum filter, PBF mobile disc vacuum filter, TC ceramic filter, GP fixed disc filter, LX full-automatic centrifuge, HVPF full-automatic vertical filter press, DY belt press dewatering machine and its control system design and system debugging services.